Add to Cart

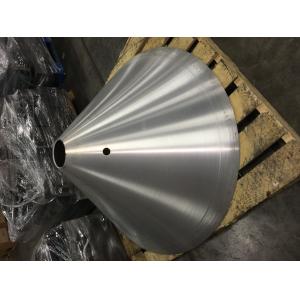

1mm Thickness Aluminum Metal Spinning Parts Aluminum Spinning Lamp Cover

Metal Spinning Parts Introduction

Because of the aesthetic requirements of the lampshade, we currently produce various metal rotary stamping lampshades to meet the needs of different places. They are made of 1mm thick aluminum alloy, which has good aesthetics and practicality. Yonglihao is a senior metal rotary stamping manufacturer , We are also committed to the manufacture of metal rotary stamping parts in the automobile industry/aerospace/telecommunications equipment and other major industries to meet the needs of customers in different industries for metal rotary stamping parts.

Metal spinning parts parameters

| Available Material (metals) | Available Material (plastic) |

| Alloy (aluminum, zinc, magnesium, titanium) | ABS, PC,ABS, PMMA (acrylic), Delrin,POM |

| Brass, bronze, beryllium, copper | PA (nylon), PP, PE, TPO |

| Carbon steel, stainless steel, SPCC | Fiberglass reinforced plastics, Teflon |

| Processes | Surface treatment (finish) |

| CNC machining(Milling/Turning), Grinding | High polish, brush, sand blast, anodization |

| Sheet metal stamping, bending, welding, assembly | plating (nickel, chrome),powder coat, |

| Punching, Deep drawing, Spinning | Lacquer painting, , silk screen, pad printing |

| Equipment | Quality control |

| CNC machining centers (FANUC, MAKINO) | CMM (3D coordinate measuring machine), 2.5D projector |

| CNC turning centers/ Lathes / Grinders | Thread gauge, hardness, caliber. A closed-loop QC system |

| Punching, Spinning and Hydraulic tensile machines | Third party inspection available if required |

| Lead time & Packing | Application |

| 7~15 days for sample, 15~25 days for production | Automotive industry / Aerospace/ Telecom equipment |

| 3~5 days via express: DHL, FedEx, UPS, TNT, etc. | Medical / Marine / Construction / Lighting system |

| Standard export carton with pallet. | Industrial Equipment & Components, etc. |

What is metal spinning?

The metal spinning method or spinning forming method is used to form a metal disc with a technique similar in concept to clay pottery carving. Usually used for short-term production, metal rotation can be done manually or automatically using a CNC lathe.

Metal rotating parts we can make

1,We have rich experience as a manufacturer and supplier various metal spinning parts, spun metal parts, metal spinnings, CNC metal spinning parts, metal spinning, spun metal parts, spinning cones, spinning rings, spinning funnels,custom spinnings, aluminum spinnings, metal spinning parts components.

2,Our group provides a single-source customized solutions using a wide variety of world-class precision manufacturing capabilities, including metal spinning, heat treating, machining, press forming and other fabrication services for virtually all workable metal alloys.

3,Our components and assemblies can be found in a wide variety of advanced applications for the aerospace, aviation, defense, energy, industrial, medical, marine markets, lamp and light industry, Lighting Equipment, Engineering, Housewares, Arts-and-crafts, Chemical industry, and Motor vehicles industry.